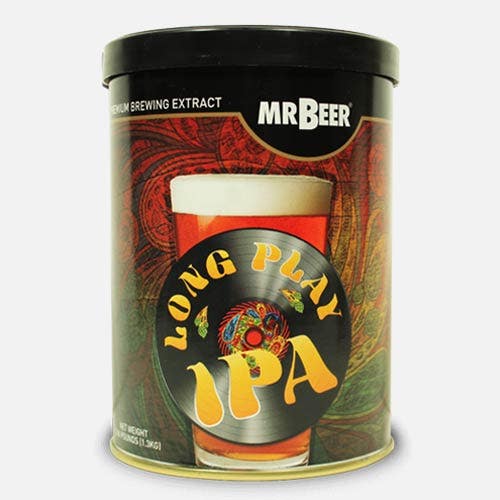

Long Play IPA Complete Beer Making Kit

- Best beer Kit for Beginners - Our beer kits are designed for the first-time brewer in mind Step-by-step instructions, simple ingredients, and easy to use brewing equipment.

- Only Takes 30 Minutes of Your Time to Brew - Using our hopped Malt extract you can brew up a batch of beer in less than 30 minutes.

- Includes the Best Ingredients to Get Started - Brewing with Mr. Beer’s Hopped Malt Extracts are perfect for any brewer. It cuts down on time, reduces the risk of contamination, and helps create a more consistent beer every time.

- Comes with Everything You Need - Our beer Kit comes with everything you need to brew your first batch of beer. No need for additional large pots, strainers, or brewing equipment. All you need is a Mr. Beer Kit, water and common kitchen items to get started.

- Satisfaction - Mr. Beer is all about simple, and efficient home brewing. If for any reason you are unhappy with your experience contact us so we can make it right for you.

Our Long Play IPA Complete Beer Making Kit comes with everything that is needed to get started brewing. This kit provides aspiring brewers with our patented brewing equipment and high-quality ingredients that simplify the Homebrewing process. Our patented brewing system includes a compact lightweight fermenter that is modeled after the design of professional brewing equipment Eleven 25oz reusable and shatterproof bottles that are specially designed for carbonating beer. We also include a can of brewing extract - a concentrated form of all-natural malted barley and hops - produced in a state-of-the-art facility by Australia's oldest family-owned brewery as well as no-rinse Cleanser and unique carbonation drops to simplify the sanitization and carbonation process. This kit is designed to brew 2-Gallons of great tasting beer.

Brewing with Mr. Beer is a relatively simple process. Below is a short instructional overview of the brewing process so you can feel confident knowing you can brew this.

Simple Brewing Process

With 16 different Refills and over 100 different Recipes, we have plenty of options available to keep the beer flowing.

What you get

Where here to help with all your brewing needs. Just give us a call, chat with us, or submit a ticket. We have brewmasters on staff to help you with your brewing journey.

STEP 1: Sanitizing

Cleaning is one of the most important steps in brewing. It kills microscopic bacteria, wild yeast, and molds that may cause off-flavors in your beer. Make certain to clean all equipment that comes in contact with your beer by following the directions below:

1. Fill clean keg with warm water to line mark 1 on the back, then add ½ pack (about 1 tablespoon) of No-Rinse Cleanser and stir until dissolved. Once dissolved, the solution is ready to use. Save the remaining ½ of No-Rinse Cleanser because you will need it for bottling.

2. Screw-on the lid and swirl the keg so that the cleaning solution makes contact with the entire interior of the keg, including the underside of the lid. Note that the ventilation notches under the lid may leak solution. Allow to sit for at least 2 minutes and swirl again.

3. To clean the spigot, open it fully and allow the liquid to flow for 5 seconds and then close.

4. Pour the rest of the solution from the keg into a large bowl. Place your spoon/whisk, can opener and measuring cup into the bowl to keep them cleaned throughout the brewing process. Leave them immersed for at least 2 minutes in cleaning solution prior to using.

5. After all, surfaces have been thoroughly cleaned, do not rinse or dry the keg or utensils. Return lid to the top of the keg, proceed immediately to brewing.

STEP 2: BREWING

Brewing beer is the process of combining a starch source (in this case, a malt brewing extract) with yeast. Once combined, the yeast eats the sugars in the malt, producing alcohol and carbon dioxide (CO2). This process is called fermentation.

1. Remove the yeast packet from under the lid of the can of brewing extract, then remove the label from the can. Place the unopened can in hot tap water

2. Using the clean measuring cup, pour 4 cups of water into your 4-quart or larger pot. Bring water to a boil, and then remove the pot from heat.

3. Open the can of brewing extract from the bottom of the can and pour it into the pot. Stir until thoroughly mixed. This mixture is the wort.

4. Fill the keg with cold water to line mark 1 on the back. The water must be cold (ideally from the refrigerator) with a temperature of 40-55°F/4-12°C. For the best results, we recommend using bottled spring water or filtered tap water. If using any other fermenter this would be approximately 1 gallon of water.

5. Pour the wort into the keg and then bring the volume of the keg up to line mark 2 by adding more cold water. Mix vigorously with the plastic spoon/ whisk. Be careful to not scratch the inside of the keg, which could create small spaces for bacteria to grow. (If you have a different fermenter top it off with cold water to the 8.5-liter mark).

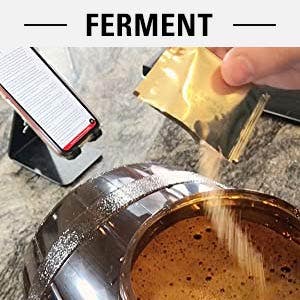

6. Sprinkle the entire yeast packet into the keg and then screw on the lid. Do not stir.

7. Allow your fermenter to sit for 10-14 days.

Store the fermenter in a cool, dark place between 68-78°F/20-26°C for the yeast to work properly. The ideal temperature range is 70-72°F / 21-22°C. After a few days, the foam and activity will subside and your batch will appear to be dormant. However, the yeast is still at work, slowly finishing the fermentation process.

STEP 3: Bottling & Carbonating

After 10 days, taste a small sample to determine if the beer is fully fermented and ready to bottle. If it tastes like flat beer, it is ready. If it’s sweet, then it’s not ready. Let it ferment for 4 more days (14 total). At this point, it is time to bottle. Do not let it sit in the fermenter for longer than 24 days total.

1. When your beer is ready to bottle, fill a 1-gallon container with warm water, then add the remaining ½ pack of the No-Rinse Cleanser and stir until dissolved. Once dissolved, it is ready to use.

2. Distribute the cleaning solution equally among the bottles. Screw-on caps (or cover with a metal cap if using glass bottles) and shake bottles vigorously. Allow to sit 10 minutes, then shake the bottles again. Remove caps and empty all cleaning solution into a large bowl. Use this solution to clean any other equipment you may be used for bottling. Do not rinse.

3. Add 2 Carbonation Drops to each 740-mL bottle. For 1-liter bottles, add 2 ½ drops; for ½-liter bottles add 1 drop. Alternatively, you can add table sugar using this table as a guide.

4. Holding the bottle at an angle, fill each bottle to about 2 inches from the bottle’s top.

5. Place caps on bottles, hand tighten, and gently turn the bottle over to check the bottle’s seal. It is not necessary to shake them.

6. Store the bottles upright and out of direct sunlight in a location with a consistent temperature between 70°-76°F or 21°-24°C. Allow sitting for a minimum of 14 days. If the temperature is cooler than suggested it may take an additional week to reach full carbonation.

Tip from our Brewmasters

After the primary carbonation has taken place your beer is ready to drink. We recommend putting 1 bottle in the refrigerator at first for 48 hrs. After 48hrs. give it a try and if it is up to your liking put the rest of your beer in the fridge. If it does not taste quite right, leave the bottles out at room temp for another week or so. Keep following this method until your brew tastes just how you like it.

This process is called conditioning and during this time the yeast left in your beer can help clean up any off-flavors. Almost everything gets a little better with time and so will your beer.