The Life Cycle of a Yeast Cell, and Yeast Management

If you want to learn all about yeast then this video is for you. Part of our new advanced education series this video covers everything about yeast!

In order to understand yeast, it’s health, management, and how that affects our beer, we first must understand how yeast lives out its life, within your beer.

First, we will discuss “What is yeast?”

Yeasts are eukaryotic, single-celled microorganisms classified as members of the fungus kingdom.

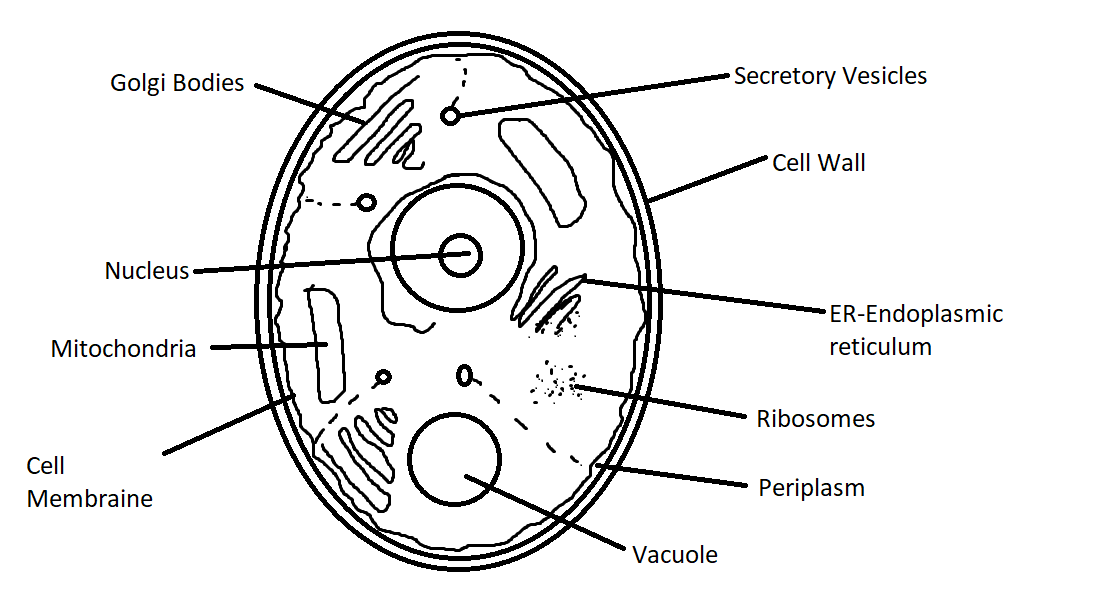

You can see here in my illustration of a yeast cell.

We can see here on the outside, this is the “cell wall”, it provides protection and shape to the cell and is also a valuable indicator of a yeast cells health and how much it has reproduced, as it begins to scar

We also see here, the “Periplasm” This is the location of the enzymes and Mannoproteins, these provide some of the primary catalysts for the fermentation process

Next, we look at the “Cell Membrane” Responsible for selective transport, metabolism, and communication. You could almost compare it to a nervous system of sorts.

Now we move onto the “nucleus” This is where the yeast cell holds its genetic material, which are the blueprints for its future offspring.

Yeast cells also contain a “Vacuole” Seen here *points* This is where Your yeast cell breaks proteins down to their amino acid building blocks, basically working like tiny disassemblers

We have also the “Mitochondria”, This is responsible for functions such as respiration ATP production. ATP stands for “Adenosine triphosphate” which is the primary source of fuel for every living thing on earth, and very important.

After that, we have the Ribosome Which is responsible for protein production

Lastly, we see the ER, Golgi, and Vesicles. These handle secretion and protein processing/trafficking

The yeast we use for brewing belongs to the class “Saccharomycetes” and we use two primary species of this yeast:

Saccharomyces cerevisiae and Saccharomyces Pastorianus (also known as Saccharomyces carlsbergensis)

Saccharomyces cerevisiae is what we know as Ale and wheat yeast. These yeasts are referred to as “Top fermenting yeasts” and this yeast is typically associated with warmer fermentation temperatures, compared to Lager or bottom-fermenting yeast varieties.

Saccharomyces Pastorianus is what we know as “Lager” yeast, which is considered bottom-fermenting and is associated with colder fermenting temperatures.

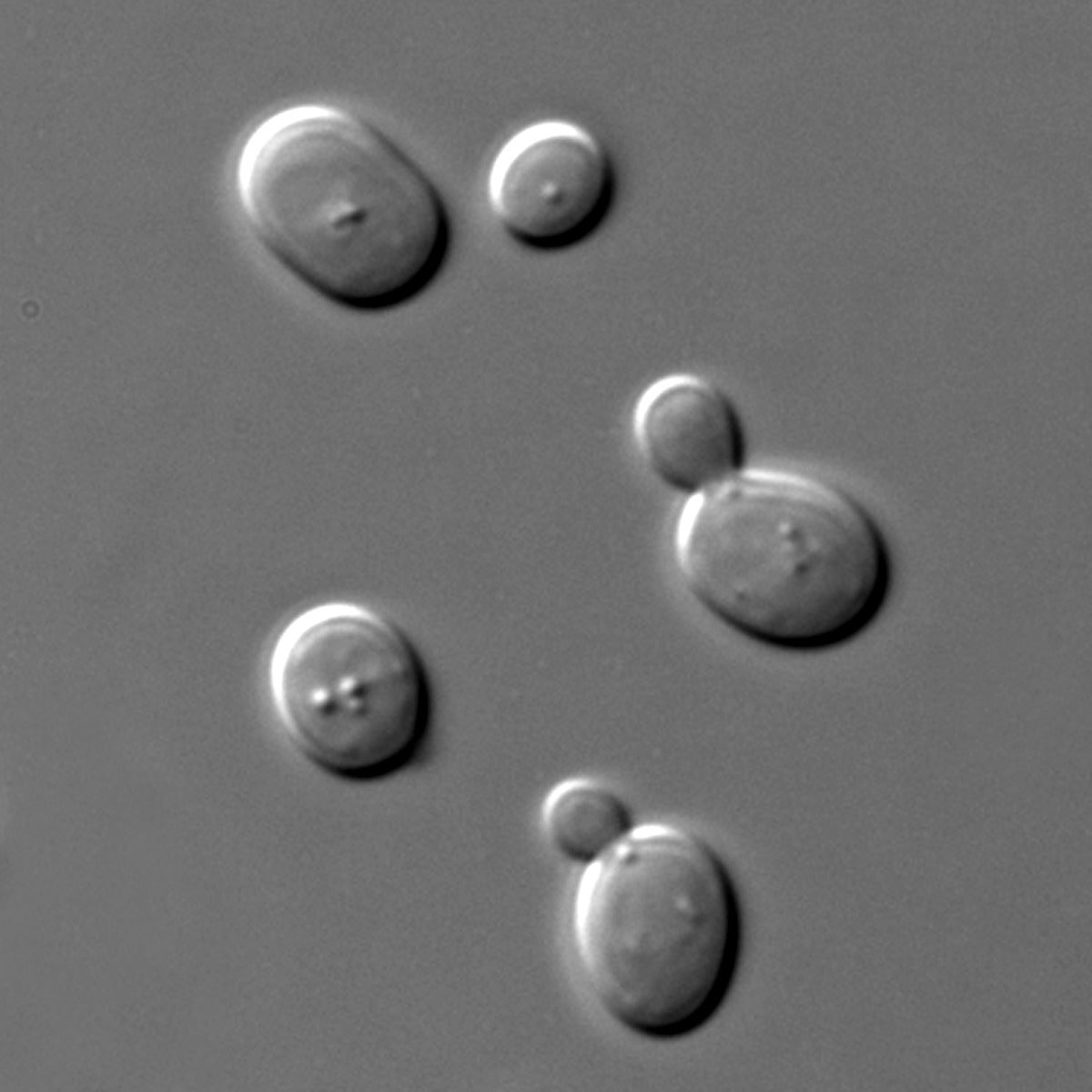

Obviously, the difference is important due to their different fermentation characteristics and requirements. You can see how they differ physically.

Figure A Saccharomyces Pastorianus and figure B is Saccharomyces cerevisiae, you can see the differences of how the cells group together between the two.

Depending on the species you are using, you will need to make considerations about your specific brewing environment, as we will discuss later, these environmental parameters dramatically impact the health of your yeast, and the overall success of an alcoholic fermentation. It’s very important to keep in mind that yeast is, indeed, a living organism and like all living organisms, it has needs!

Now that we understand yeast a little better, and what it is… Let’s talk about its life cycle and as we move through that, I will talk about points of yeast health and management that apply to that stage.

In this talk, we will mostly be discussing these subjects, in terms of dry yeast. Everything here will apply to hydrated yeast starters as well, with some subtle nuances.

Let’s start where our yeast first meets our wort, the pitch!

When your yeast is first pitched into your wort, it enters something called the “lag phase” This is when your yeast is acclimating to its environment. This period lasts typically, anywhere between 3-15 hours respectively.

During this time, the yeast begins to uptake the essential minerals and amino acids that it will use as protein building blocks. Whatever the yeast cannot get from the wort, it will attempt to manufacture itself, like any other living organism, yeast needs a full spectrum of nutrients to perform its job and basically live a happy life and complete a healthy fermentation.

As the nutritional needs of the yeast are met during the lag phase, the yeast begins to manufacture necessary enzymes. Oxygen is also extremely important to yeast during this period, as yeast cells require it to build up the cell walls and create adequate yeast vitality, and better vitality and viability generally mean cleaner tasting beer in the long run.

Let’s take a moment and talk about why this lag phase is important when it comes to the entire process of our fermentation.

During the initial hydration, if you are pitching dry yeast, or even initially making a starter, yeast can lose on average, 30-50% of its viability, and that is in ideal conditions, that number can be higher if the yeast is already in bad shape (which is usually because it’s old or expired) or if we are introducing the yeast to an environment that is not ideal, such as wort that is too warm, too cold, or lacks the appropriate nutrient profile or oxygen content, or if your pitch was simply too small, to begin with.

If you are working with a low number of viable cells during the LAG, or your wort does not contain the required nutrients, vitamins and oxygen, yeast can struggle to move through this phase and into its exponential growth phase (log which we will discuss next), This because the yeast is under stress and stressed yeast takes longer to start budding and making it’s catalyzing components in order to begin the process of fermentation. If the wort is too cold, this can also impede the lag phase. Our goal when we brew is to move through the lag phase successfully with adequate nutrient uptake so that we maintain many viable mother cells. Without viable mother cells, our yeast can not produce the number of daughter cells needed to reduce the total stress and properly distribute the labor of fermentation to keep up, as older cells begin to die off, later. In my opinion and the option of many other brewers, having an adequate number of initial yeast cells is even more critically important if you are naturally carbonating your beer, using priming sugar.

If our yeast pitch is too small or has low total viability due to the earlier mentioned factors, it can also give wild bacteria and pathogens an opportunity to become the dominant organism in the beer, right out of the gate. Leading to infection. Basically, you are leaving a door open.

If your yeast cells are damaged or stressed during LAG, your production of off-flavors can potentially be much higher, which can follow you all the way to bottling!

What do we do about this as far as yeast management is concerned? As a brewer, I always look first at my pitch rate, Followed by the initial parameters of your starting wort. This includes temperature, oxygenation, and wort nutrient profile.

As far as pitching is concerned to keep in mind, in homebrewing it is difficult to truly overpitch to a detriment, so if you are getting off flavors routinely, upping your yeast may be in order, especially if you struggle with temperature management, or your lag times seem to be longer than that 15-hour window. It’s important to note that while very long lag times are not ideal, neither is the opposite in all cases, because this a critical acclimation stage, so we want to give the yeast enough time to build strong cell walls, and uptake everything it needs to be healthy. An hour-long lag might be exciting, but precocious yeast tends to not be quite as happy long term.

You can think of your Lag phase as the “formative” stage of your yeast, so it’s important to set yourself up for success, from the very beginning.

I cannot stress enough, AERATION. It is so critically important to make sure your wort contains ample oxygen before pitching. I mention this because in my experience the two most common reasons for high, unwanted ester production early on, are under pitching, and under aeration. Again, these are not the only possible negative variables, but they are the most common especially within extract and partial mash brewing.

Also, when it comes to yeast, it loves an all-malt wort because of the full spectrum of nutrition it provides, some examples of necessary vitamins are riboflavin, inositol, and biotin. Important minerals are phosphorous, Sulphur, copper, iron, zinc, potassium, and sodium. So, if you are brewing a wort that has a high amount of adjuncts like corn sugar or cane sugar, these tend to lack the nutrients needed for proper yeast health, leading to stress and off-flavor production. Therefore, beverages fermented with cane sugar or corn sugar like seltzer, are usually dosed with extraneous nutrients as yeast cannot live well off these simple sugars, alone.

So now that we have covered the Lag phase, let’s talk about our yeast as it transitions into Log, otherwise known as the exponential growth phase.

This phase can last anywhere between 1-4 days This is the phase where we visually see the fermentation start to take off by way of the Krausen layer. As the yeast comes out of the lag phase, it starts to consume the sugars in solution. And large amounts of CO2 are produced.

The term Log stands for Logarithmic because the yeast is increasing its activity and rapidly budding, creating additional exact copies of itself, called Daughter cells. This is a form of vegetative growth, is asexual and ideal when it comes to brewing as it allows the mother cells nucleus to split and provide the daughter, or bud, with an exact copy of the parent's DNA.

The yeast will quickly and aggressively consume the available wort sugar and start to convert them into ethanol at this time. This is usually the time you will see large amounts of turbulence occurring within your fermenter, almost like it was being stirred.

That is the intense and aggressive metabolic action of the yeast occurring on a visible level.

The exponential growth phase is made possible by the rapid consumption of wort sugars by yeast. It’s important to note that wort sugar is consumed by yeast in a certain pattern. Glucose is used first, then fructose and sucrose. These are simple sugars and can be quickly shuttled into metabolism, giving a quick burst of energy. The glucose concentration in wort is roughly 14 percent of wort sugars.

Next, the wort will go after the more complex Maltose which accounts for up to more than half of your wort sugars

Maltose is an incredibly important contributor to flavor, it’s what gives you perceptible grist notes and even influences the flavor that yeast contributes.

Maltose is important also because it has the ability to turn on 5 of the genes found in a yeast cell's DNA, this is what sends the message to the yeast cell that it’s time to start fermenting. Maltose is taken up into the cell via a transport mechanism. Since Maltose is a more complex Disaccharide, it is taken up by something called a Proton Coupled symport mechanism. This is more labor-intensive for the yeast, but this is where your yeast is really going to get it’s fermenting power. The monosaccharides that your yeast used first, like glucose and fructose are transported more simply by something called facilitated diffusion.

After the Maltose has been taken in, it is converted into glucose using Maltase enzymes. After this process, the yeast now has fermentable glucose to munch on and turn into alcohol.

Lastly, your yeast moves onto the trickiest sugar to digest called maltotriose. It is important to remember that some yeasts are better at fermenting this carbohydrate than others, and some can not ferment it at all. The ability of a strain to ferment Maltotriose is what contributes to its individual attenuation rage. And when we talk about attenuation we are basically talking about how fully a yeast will ferment, available malt sugars within our wort, including maltotriose.

You may hear some yeasts described as very dry, this is referring to their high attenuation potential.

So let's discuss some important yeast management parameters to consider during the LOG phase before we move on.

As we have mentioned, LOG is the most active stage of fermentation, this is the high-intensity workout portion of the process for your yeast cells, and the height of their metabolic activity.

Because of this, you may notice that your yeast generates quite a lot of heat. Because of this added heat, some brews can benefit from being fermented a couple of degrees lower during log to offset this heat production and slow down the yeast growth just a bit, in order to mitigate the production of too many esters, primarily the undesirable ones. This is another instance where surprise surprise, pitch rate is again, vitally important because starting with an adequate pitch means your yeast has to grow less and has lower stress put on it, to get the job done… helping to maintain the integrity of your flavors and prevent your brew from stalling out as well.

Now let’s move to the final stage of your fermentation process.

Enter the stationary phase: This can be anywhere from 3-10 days depending on your yeast, but in most cases with typical brewing yeasts (excluding certain fast fermenters like kiviek).

At this point, yeast growth slows down, and yeast enters the stationary phase of growth. Most of the flavor and aroma compounds have been produced, including fusel alcohols, esters, and sulfur compounds. The beer is referred to as green because it does not yet have the acceptable balance of flavors. If you had brewed a batch or two, you have probably noticed your beer tastes different before it is conditioned and this is where that green apple or butter flavor can usually be most apparent, especially if the yeast has been under stress and or there has been a significant amount of yeast growth because the batch was under pitched. We will discuss that in more detail, shortly.

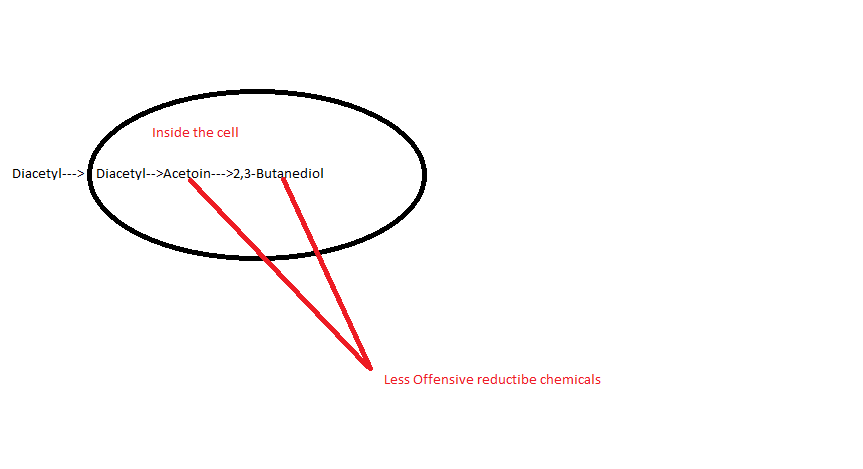

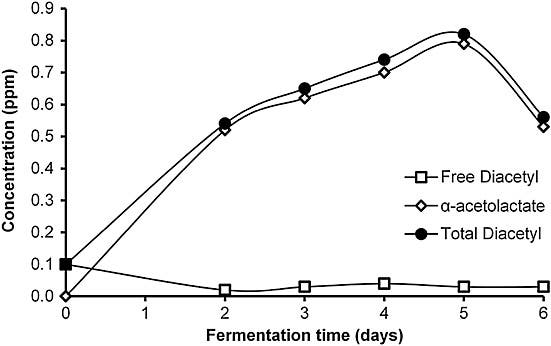

We mature and condition beer in the stationary phase. At this point, Krausen has fallen, and yeast begins to flocculate. This is the time that yeast really starts to clean up after themselves. They intracellularly reduce undesirable compounds, into their more acceptable reductive chemicals. A very notable compound that is reduced during this phase is the ketone, Diacetyl. So let’s talk about Diacetyl for a moment. Diacetyl is a byproduct of yeast; they ALL produce it to certain varying degrees and it’s almost always considered an off-flavor with some very particular exceptions, like the ESB style.

Diacetyl is characterized by a butterscotch or buttered popcorn flavor in your beer. The flavor threshold for Diacetyl in home-brewed beer is about .05 ppm to 1.0ppm, but some pallets can detect it at even the most minute levels.

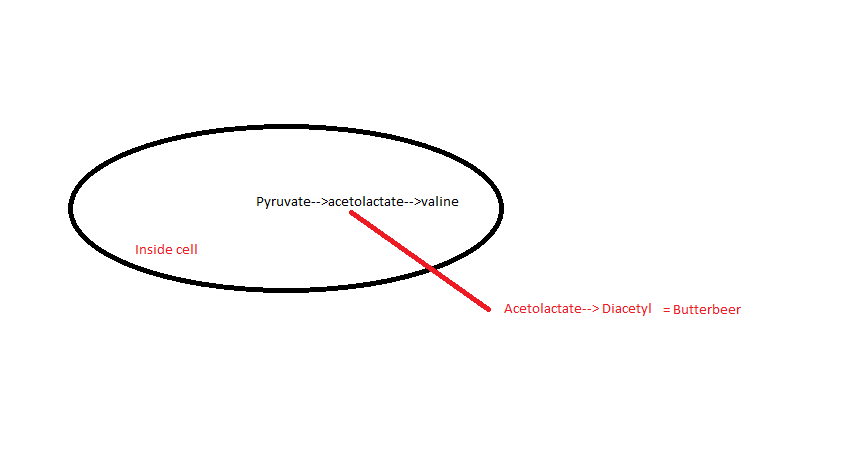

Diacetyl can become noticeable in your beer when one of the precursors within the yeast cell, acetolactate is leaked from the yeast cell, instead of being converted to Valine, within the cell. That Diacetyl that leaked into your beer can be reduced during the stationary phase of fermentation. The yeast reabsorbs this ketone and uses enzymes to break it down into it’s reductive, and less offensive chemicals, Acetoin, and butanediol.

So what do you do if you find yourself with a beer full of diacetyl during your stationary phase?

You have probably heard the term “Diacetyl rest” at one point or another. The concept is pretty simple. Diacetyl reduction slows way down at cooler temps. That is why it’s usually more of an issue in cold fermented Lager style beers, but it can also show up in heavily dry-hopped ales, as well.

In these cases, we employ a diacetyl rest procedure to reduce that. For lagers, we usually raise the temperature to 65-68 for the last two or so days of fermentation or about 2-5 specific gravity points from the target terminal gravity. For ales, the reduction of diacetyl is much the same, except for different temperature parameters, so if you are fermenting your ale at say 70, you may only need to bring your rest temp up a degree or two.

Here we can see a general depiction of the expression, of diacetyl, and the beginning of its reduction

It’s worth noting that Diacetyl can also be caused by a bacterial infection usually by Either pediococcus or lactobacillus bacteria, this is a whole subject on its own, so for the sake of time we will save that for an episode on infections.

So let’s go back to that green apple flavor we mentioned earlier, what chemical causes that? The culprit is Acetaldehyde! Brewing yeast produces acetaldehyde as an intermediate compound during the conversion of glucose to ethanol. This chemical is produced in every beer, usually during the earlier fermentation stages. In a healthy fermentation, the yeast is usually able to the convert the majority of acetaldehyde into alcohol so that it can no longer be tasted, but if you had factors earlier on in your fermentation process like off temps, under pitching, poor aeration, or overexposure to oxygen after the wort has become beer, your acetaldehyde will fail to fully convert to alcohol, and BOOOOYYYY will you taste it!

Speaking of oxygen exposure, this can become even more complex if, during that exposure, your beer is also exposed aerobic bacteria, and those bacteria covert your Acetaldehyde into acetic acid, which you guessed it… that’s vinegar. Gross!

Acetaldehyde is the most common indicator, in my experience of a stressful fermentation, and the number one cause for most homebrewers that I see is under pitching or untimely exposure to oxygen. Are you starting to notice a pattern here with pitch rate? What do we do if we are beyond that point, and we can’t go back to the beginning? The answer is usually time and conditioning.

That’s where natural conditioning and carbonating can come in very handy! First, if you have completed fermentation, meaning that there are no longer gravity drops occurring in your beer, bottling it and adding priming sugar, acts to wake the yeast back up, and send them back to work. Not only will they have the ability to consume some additional sugars to make C02, but they will have an opportunity to reabsorb more of those off-flavors and convert them into more desirable compounds.

Speaking of our LBK for a moment, it can be tempting to leave it in there for a longer amount of time, thinking this flavor will clean up…. You’re not entirely wrong in that thinking, but you are overlooking a critical factor…. Over oxygenation encourages the expression of Acetaldehyde, if your ending SG has been reached, there’s not enough C02 being produced to push oxygen away from your beer anymore, effectively making the problem worse. By bottling, you stop that unwanted exposure. Then your beer is left to condition and clean up in a far more controlled environment. Now, this can apply to other fermenters too, but it is important to remember especially in fermenters that are not using a traditional bung and airlock system. BUT as I touched on earlier, it’s a little bit of a catch 22, Because a lack of good aeration during our LAG phase, will also set us up for Acetaldehyde expression later as well. A good rule of thumb I always try and keep in mind is Oxygen is great for wort, not so great for beer.

It can also be helpful to condition your bottles, at a warm enough temperature at least initially, so that your yeast is able to work quickly and efficiently, conditioning too cold can cause further stress on already tired, old yeast cells, and further complicate your green apple flavor, and other “off” indicators.

Alright, guys so let’s go over some of what we have learned today…. I think it’s become very clear that proper yeast management from beginning to end, is tantamount to be a successful brewer. Some of the most critical factors being Yeast pitch rate, temperature, and wort quality.

You can think of a yeast pitch like a construction crew, the more healthy, viable workers that are on that crew, the better, and faster the job can be accomplished. If we provide the yeast with enough environmental support, through proper temperature, mineral and nutrient base, and aeration…. Those incredible little cells will pay you dividends.

I hope you enjoyed this, and I hope it helped to enrich your knowledge and understanding of yeast, it’s life cycle, and its contribution to your beer. Believe it or not, there’s still lots about yeast we didn’t get a chance to cover, but hopefully, this will inspire you to continue to bolster your knowledge and understanding of yeasts.

Thank you for nerding out with me on one of my favorite subjects, and please come back and join us next week for another episode of “Brew talk with Mr. Beer” with Robert! I hope to do these advanced education talks as often as possible, as long as there’s a demand. If you have suggestions on topics for a future Advanced education talk, please let us know.

Cheers guys, and happy brewing!

Ashley